- 20 Apr 2025

Can we charge a tractor battery with an inverter?

When your tractor battery dies unexpectedly, especially during crucial farming operations, finding an immediate solution becomes a priority. Farmers and equipment operators in Sydney and beyond often wonder: Can you charge a tractor battery using an inverter? This question arises frequently, particularly in remote locations where conventional charging methods may not be readily available.

In this comprehensive guide, we’ll explore the feasibility, methods, safety considerations, and best practices for using an inverter to charge batteries for agricultural equipment. Whether you’re a seasoned farmer or a hobby gardener with a small tractor, understanding your power options can save you time, money, and frustration when your tractor battery loses its charge.

Understanding Tractor Batteries and Their Charging Requirements

Before attempting to charge a tractor battery with alternative methods, it’s important to understand what makes these batteries unique and how they typically receive a charge.

What Makes Tractor Batteries Different

Tractor batteries are designed to deliver high cranking power for starting large engines, often in challenging weather conditions. Unlike car batteries, they typically:

- Have higher cold cranking amp (CCA) ratings

- Feature thicker plates to withstand vibration

- Provide sustained power for longer operational periods

- Are built to endure harsh agricultural environments

In Sydney’s varying climate, from hot summers to mild winters, a properly functioning tractor battery is essential for reliable farm operations throughout the year.

Normal Charging Methods for Tractor Batteries

Conventionally, farmers charge battery systems on tractors through:

- The tractor’s alternator during normal operation

- Dedicated agricultural battery chargers

- Jump-starting from other vehicles

- Specialized farm equipment charging stations

When these traditional methods aren’t available, alternative solutions like using an inverter come into consideration.

Can You Use an Inverter to Charge a Tractor Battery?

The short answer is: it depends on the type of inverter you have and how you approach the process.

Understanding Inverters and Their Function

An inverter is designed primarily to convert DC (direct current) power from a battery into AC (alternating current) power that can run household appliances. Most standard inverters are not built to work in reverse—they don’t naturally convert AC back to DC to charge batteries.

However, there are solutions involving inverters that can help in emergency situations:

Types of Inverters Relevant to Battery Charging

- Standard Inverters: Convert DC to AC only

- Inverter/Chargers: Dual-function devices that can both convert power and charge batteries

- Modified Sine Wave Inverters: Less expensive but potentially problematic for sensitive electronics

- Pure Sine Wave Inverters: Produce clean power that’s safe for all devices

For Sydney farmers looking to invest in versatile power solutions, an inverter/charger combination might be the most practical option for occasional tractor battery charging needs.

Methods to Charge a Tractor Battery Using an Inverter System

If you find yourself needing to charge a tractor battery with an inverter setup, here are the viable approaches:

Method 1: Using an Inverter/Charger Combination

These specialized units are designed specifically to perform both functions:

- Connect the inverter/charger to a power source (generator, solar panels, or mains power)

- Set the device to charging mode

- Connect to the tractor battery following proper polarity

- Monitor the charging process to prevent overcharging

Many farmers in Sydney with remote properties find these units invaluable during power outages or when working far from electrical outlets.

Method 2: Inverter + Separate Battery Charger Approach

This indirect method involves:

- Using your inverter to convert DC power from a secondary source (like a car battery) to AC power

- Plugging a standard battery charger into the AC output from the inverter

- Using that charger to charge the tractor battery

This solution works in emergencies but is less efficient due to energy losses during the double conversion process.

Method 3: Solar Panel + Inverter System

For sustainable farming operations in Sydney, a solar system can:

- Collect solar energy through panels

- Store power in a battery bank

- Use an inverter to regulate power

- Connect to a charge controller

- Safely charge battery systems for tractors and other equipment

This eco-friendly approach has gained popularity among environmentally conscious farmers looking for renewable ways to maintain their equipment.

Safety Considerations When Charging Tractor Batteries with Inverters

Safety should always be your primary concern when attempting to charge a tractor battery using alternative methods.

Electrical Safety Precautions

- Always ensure proper polarity (connecting positive to positive, negative to negative)

- Wear appropriate safety gear (gloves, eye protection)

- Work in a well-ventilated area away from flammable materials

- Disconnect the battery from the tractor before charging when possible

- Never charge a frozen battery

In Sydney’s occasionally humid conditions, also be mindful of moisture when working with electrical equipment.

Preventing Battery Damage

To protect your valuable tractor battery when charging with an inverter:

- Use the correct charging voltage for your specific battery type

- Avoid fast-charging unless absolutely necessary

- Don’t overcharge—monitor the process or use a charger with automatic shutoff

- Keep the battery at a moderate temperature during charging

- Check electrolyte levels in non-sealed batteries before charging

Inverter Capacity Considerations

Your inverter must have sufficient capacity to handle the charging requirements:

- Ensure the inverter can supply enough wattage for your battery charger

- Verify that the power source supplying the inverter is adequate

- Allow for cooling during extended charging operations

- Don’t exceed the inverter’s duty cycle ratings

Step-by-Step Guide to Charging a Tractor Battery with an Inverter

If you’ve determined this approach is appropriate for your situation, follow these detailed steps to safely charge your tractor battery:

Preparation

- Gather necessary equipment:

- Inverter (preferably inverter/charger)

- Power source for the inverter

- Battery cables with appropriate connectors

- Safety equipment

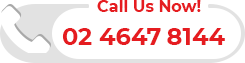

- Voltmeter for testing

- Check your battery:

- Examine for physical damage

- Test current voltage

- Inspect terminals for corrosion

- Check electrolyte levels (if applicable)

- Position equipment:

- Place in a well-ventilated area

- Ensure stable positioning

- Keep away from combustible materials

- Provide adequate spacing for cooling

Connection Process

- Power off all equipment before making connections

- Connect the inverter to its power source according to manufacturer’s instructions

- If using the inverter + charger method:

- Connect the inverter to the power source

- Connect the battery charger to the inverter

- Connect the charger to the battery following the correct polarity

- If using an inverter/charger:

- Set to the appropriate charge mode for your battery type

- Connect directly to the battery terminals, respecting polarity

- Secure connections to prevent disconnection during charging

Monitoring the Charging Process

- Begin charging at a low rate, especially for severely discharged batteries

- Monitor battery temperature—excessive heat indicates problems

- Check voltage periodically to track charging progress

- Observe the inverter for signs of overheating or strain

- Be prepared to intervene if any issues develop

Completing the Charge

- Allow the battery to reach full charge (typically 12.6-12.8 volts for a 12V battery)

- Disconnect in reverse order of connection

- Test the battery voltage after it rests for 1-2 hours

- Reinstall in the tractor if voltage reading indicates a successful charge

- Document the process for future reference

Common Challenges When Using Inverters to Charge Tractor Batteries

Farmers in Sydney and elsewhere report several recurring issues when attempting to charge tractor batteries with inverters:

Insufficient Power Output

Many standard inverters lack sufficient power to effectively charge a large tractor battery. Solutions include:

- Upgrading to a higher-capacity inverter

- Using a specialized inverter/charger with sufficient output

- Extending charging time to compensate for lower output

- Employing multiple-stage charging techniques

Battery Will Not Hold Charge

If your tractor battery charges but quickly discharges, the problem may be with the battery itself:

- Test for internal shorts or damaged cells

- Check for parasitic drains in the tractor’s electrical system

- Consider battery replacement if it’s beyond its useful life

- Evaluate sulfation and consider desulfation techniques

Inverter Overheating

During extended charging sessions, inverters may overheat:

- Ensure adequate ventilation around the inverter

- Consider adding auxiliary cooling fans

- Reduce charging amperage to decrease heat generation

- Implement intermittent charging with cooling periods

Compatibility Issues

Not all charging systems work well together:

- Ensure your charger is compatible with the inverter’s output type

- Verify that your battery type matches your charging profile

- Check for appropriate voltage and amperage ratings

- Consider using a power conditioner for sensitive equipment

Alternative Solutions for Emergency Tractor Battery Charging

When an inverter isn’t available or suitable, Sydney farmers have several other options to charge a tractor battery:

Solar Charging Systems

Increasingly popular in sunny Australia, solar solutions offer:

- Renewable energy source

- Portability options for field charging

- Low operating costs after initial investment

- Environmental benefits

Generator-Powered Charging

For remote locations:

- Portable generators can power conventional chargers

- Higher charging capacity than most inverter systems

- Independence from fixed power infrastructure

- Ability to handle multiple batteries

Battery-to-Battery Charging

In emergency situations:

- Using another vehicle to jump-start

- Portable jump packs designed for agricultural equipment

- Battery paralleling for slow charging

- Battery swapping from similar equipment

Maintenance Tips to Minimize Emergency Charging Situations

The best solution is preventing battery failure in the first place. Proper tractor battery maintenance includes:

Regular Testing and Inspection

- Check voltage levels monthly

- Inspect terminals for corrosion

- Verify secure mounting to prevent vibration damage

- Test charging system output regularly

Proper Storage Practices

When tractors sit idle in Sydney’s off-season:

- Disconnect batteries or use a battery disconnect switch

- Apply a maintenance charger or trickle charger

- Store in climate-controlled environments when possible

- Maintain electrolyte levels in conventional batteries

Addressing Early Warning Signs

Be proactive when you notice:

- Slower engine cranking

- Dimming headlights

- Electrical system irregularities

- Need for more frequent charging

Cost Considerations: Inverters vs. Traditional Charging Methods

For farm operations in Sydney evaluating different charging options, consider these financial factors:

Initial Investment

- Dedicated tractor battery chargers: $100-300

- Quality inverter/chargers: $200-1,000+

- Solar charging systems: $300-2,000+

- Premium battery brands with longer life: $150-400

Operational Costs

- Electricity costs for conventional charging

- Fuel costs for generator-powered options

- Maintenance expenses for each system

- Replacement frequency based on the charging method

Return on Investment Analysis

- Calculate battery lifespan extension with proper charging

- Factor in downtime costs during emergency charging

- Consider productivity improvements with reliable power

- Evaluate versatility benefits of multi-purpose equipment

Expert Opinions: What Agricultural Specialists Say About Using Inverters to Charge Tractor Batteries

We consulted with several agricultural equipment specialists in Sydney regarding using inverters to charge tractor batteries:

“In emergencies, a proper inverter/charger can definitely get you out of trouble, but it shouldn’t replace conventional charging methods for regular use. The charging profiles aren’t optimized for long battery life,” explains James Wilson, agricultural equipment maintenance specialist.

Battery expert Sarah Thompson adds: “The key is matching your inverter’s output to your battery’s requirements. Many farmers damage batteries by using improper charging methods when in a hurry.”

Conclusion: Is Charging a Tractor Battery with an Inverter Viable?

To summarize our findings on whether you can charge a tractor battery with an inverter:

Yes, it is possible to use an inverter system to charge a tractor battery, but with important qualifications:

- A true inverter/charger combination provides the most reliable solution

- Standard inverters require additional equipment (separate battery charger)

- Safety precautions must be strictly followed

- The process is best reserved for emergency situations rather than routine maintenance

For Sydney farmers and equipment operators, investing in a quality charging system appropriate for agricultural use remains the recommended approach. However, understanding how to safely use an inverter to charge battery systems in emergencies provides valuable flexibility when conventional methods aren’t available.

By following the guidelines outlined in this article, you can safely address battery charging needs while protecting your valuable equipment and ensuring you stay productive even when faced with power challenges.

Remember that proper maintenance and regular charging with appropriate equipment remains the best strategy for maximizing your tractor battery’s lifespan and reliability, keeping your agricultural operations running smoothly throughout the year.